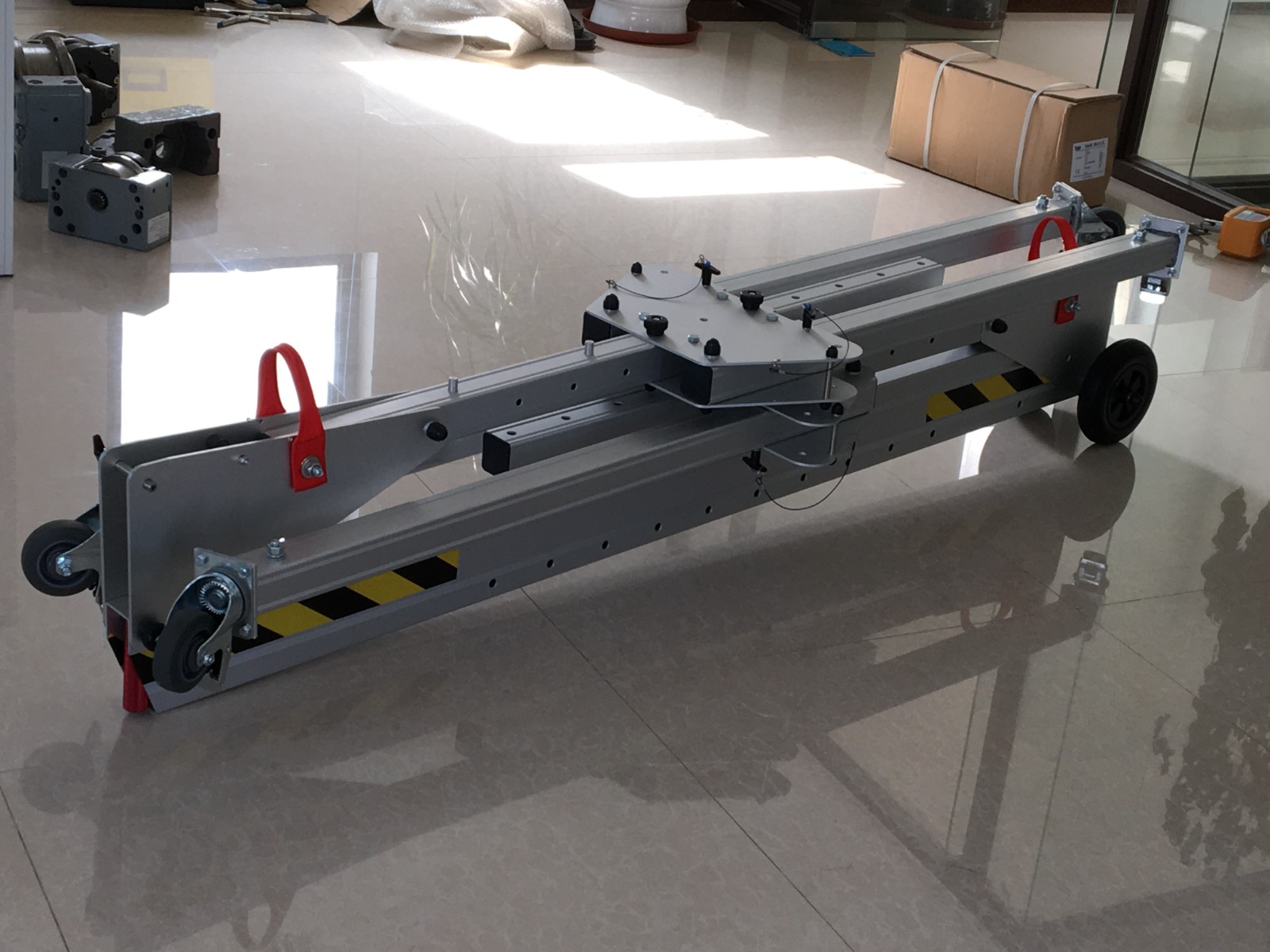

The cleanroom foldable aluminum gantry crane is made of aluminum alloy, meets the hygiene standards of the cleanroom, and is easy to clean and maintain. The equipment has a folding function to save space and improve flexibility. Through its stable structure and high load capacity, it can provide excellent operating efficiency and safety while saving space. It is an ideal choice for material handling in the cleanroom. We will explore the main advantages of the cleanroom foldable gantry crane to provide effective help for customers to choose.

Space Saving

The design of the foldable aluminum gantry crane allows it to be folded and stowed when not in use, which greatly saves floor space. The gantry crane can maximize the use of space in the cleanroom while keeping the passage unobstructed for the flow of other equipment and personnel.

Flexible Adaptation

The cleanroom foldable gantry crane is highly flexible and can be quickly moved between different work areas as needed. Its folding function allows the equipment to easily adapt to different work scenarios and changes in demand. It can be unfolded and used when needed, quickly folded when not in use, providing great operational flexibility and convenience.

Comply with Cleanroom Standards

Cleanrooms have strict requirements for the cleaning and maintenance of equipment. Foldable aluminum gantry crane is usually made of aluminum alloy, which reduces the accumulation of dust and particles and is easy to clean and maintain. Its seamless connection and sealing design meet the high cleanliness standards of clean rooms, ensuring the normal operation of equipment in high-demand environments.

Easy Maintenance and Care

The design of the aluminum gantry crane simplifies maintenance and care. The folding mechanism of the equipment not only facilitates storage, but also makes it easier to inspect and clean the equipment. Regular maintenance can effectively extend the service life of the equipment and ensure its continued efficient operation.

Enhanced Safety

The structural design of the foldable gantry crane is not only stable and firm, but also equipped with overload protection devices and safety locking mechanisms to ensure that no unexpected situations occur during handling. The folding function of the equipment also helps to reduce potential safety hazards in the work area.

Application Scenarios of Foldable Aluminum Gantry Crane

Semiconductor manufacturing: Handling and assembly of precision materials.

Pharmaceutical industry: Material handling during drug production.

Biotechnology: Handling of key experimental and production equipment.

Foldable aluminum gantry cranes have become important equipment in modern cleanroom environments due to their space-saving, flexible adaptation, efficient operation and compliance with cleanroom standards. Choosing KUNFENG CRANES will bring you excellent performance and significant benefits for your industrial operations.

Related Product: Foldable Mobile Gantry Crane for Cleanrooms