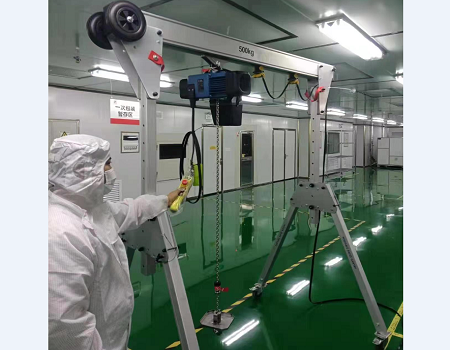

Cleanroom foldable mobile gantry crane is a highly flexible lifting equipment designed for clean environments, with a foldable structure, excellent material compatibility and high-precision operating capabilities.

A foldable mobile gantry crane for cleanrooms is a type of lifting equipment designed specifically for cleanroom environments. It combines the traditional advantages of a gantry crane (such as high stability and large lifting capacity) with modern foldable features for easy use in strictly controlled environments. This type of equipment is particularly suitable for efficient lifting operations that require frequent movement or in situations where space is limited.

Structural components

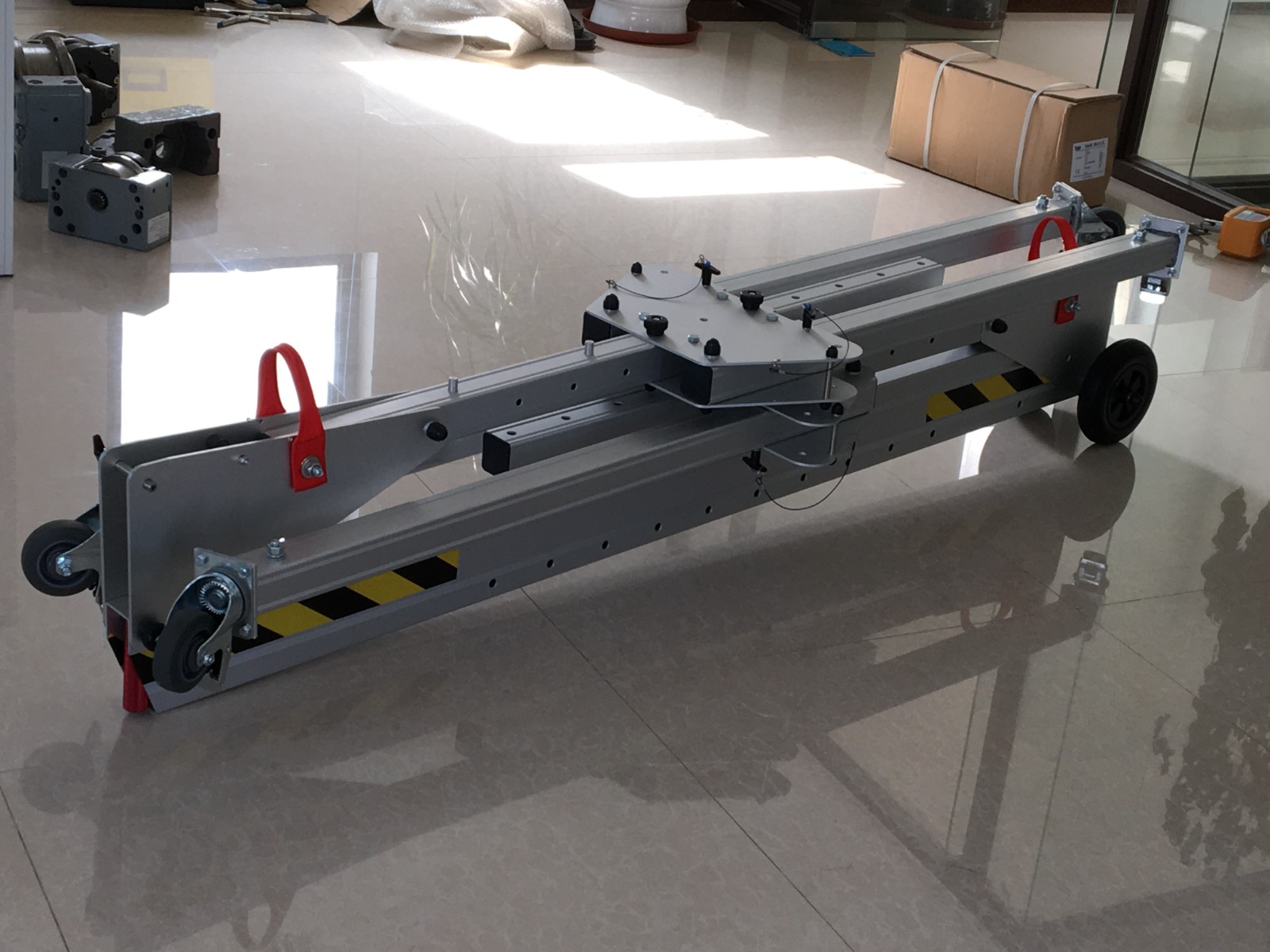

● Main beam: The main beam that supports the lifting operation, which can withstand large loads and is usually designed as a foldable structure for easy transportation and storage.

● Column: The vertical structure that supports the main beam, which is usually also designed to be foldable to save space and increase flexibility.

● Crossbeam: Lateral support that increases the stability of the frame and ensures the balance of the lifting operation.

● Wheels: Installed at the bottom of the frame or the bottom of the column, it is convenient for the equipment to move in the cleanroom. The wheels are usually equipped with a locking device to ensure stability during operation.

● Moving device: Includes a high-precision guide device to ensure stability and accuracy when the equipment is moved.

● Electric hoist: Provides lifting function and can accurately control the lifting and lowering of the load.

● Remote control device: Some models are equipped with wireless remote control, which allows operators to remotely operate the equipment in the clean room, improving operational safety.

Overload protection: Automatically stops when the load exceeds the safety limit to protect the equipment and operators.

Product advantages

● The equipment can be folded when not in use for easy storage and transportation, especially suitable for clean room environments with limited space.

● Select materials and designs that meet the requirements of clean rooms, such as stainless steel or aluminum alloy, to reduce particulate pollution and corrosion problems.

● It can be flexibly moved in the clean room to adapt to different working positions and angles, and improve work efficiency.

● The equipped safety device can effectively avoid operating accidents and ensure the safety of equipment and personnel.

● The high-precision movement and control system ensures the accuracy and stability of lifting operations.

Use scenarios

● Semiconductor production: used to transport semiconductor materials and components in clean rooms, with extremely high requirements for environmental cleanliness.

● Pharmaceutical industry: suitable for equipment and material handling in pharmaceutical clean rooms to maintain environmental hygiene and product quality.

● Optical instrument manufacturing: used for material and equipment handling in optical instrument production lines, maintaining high precision and cleanliness.

● Electronic equipment assembly: During the assembly of electronic products, move and position equipment and components to improve production efficiency and accuracy.