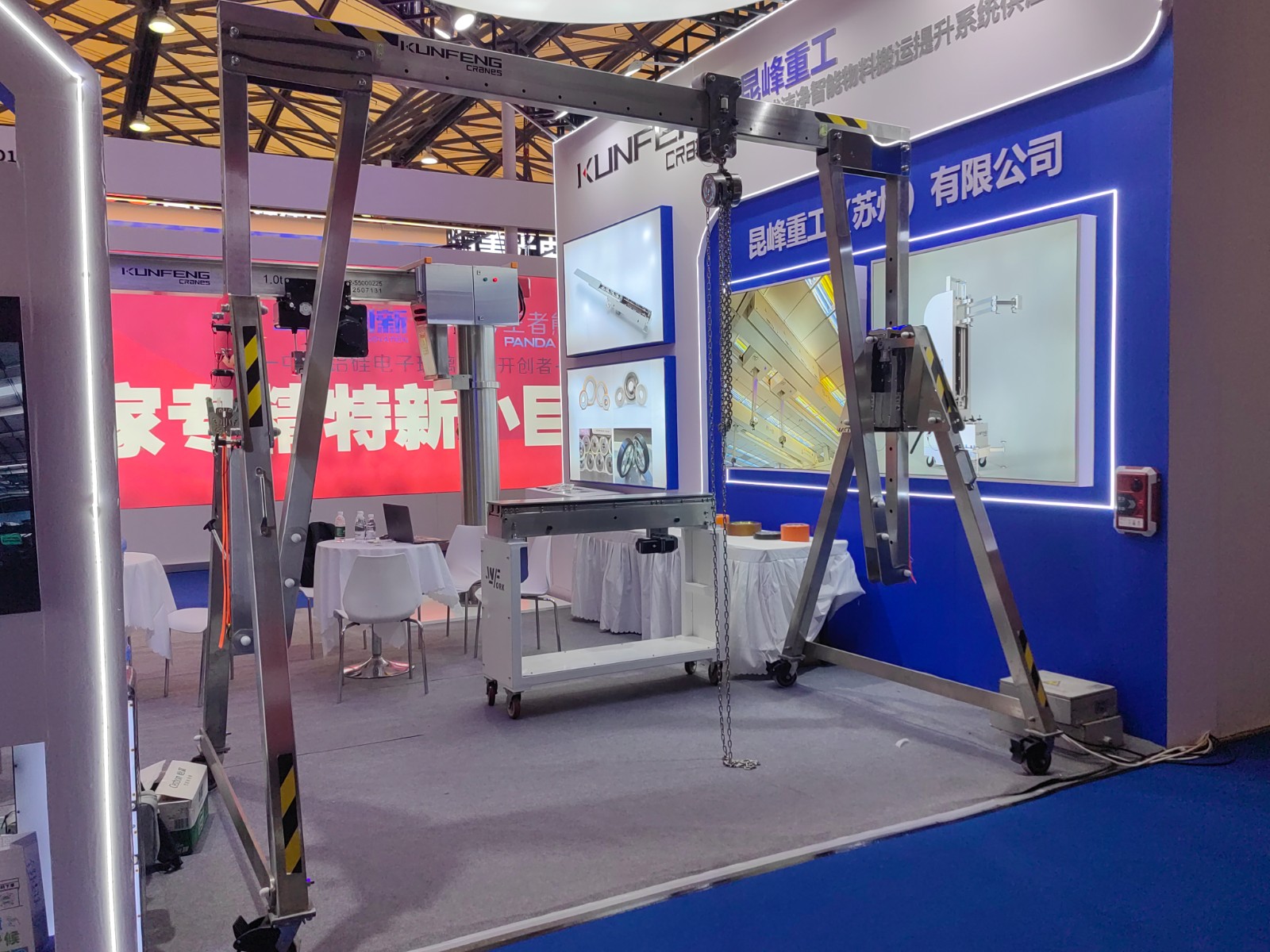

The stainless steel chain hoist gantry crane, characterized by excellent material quality, flexible operation, stable structure, and easy maintenance, has demonstrated significant advantages in industries with high requirements for cleanliness and corrosion resistance, providing reliable support for material lifting operations in industrial production.

All stainless steel corrosion-resistant structure

The main frame, columns, and beams of the gantry crane, as well as core components such as the chain and hook of the chain hoist, are mostly made of 304 stainless steel, which has strong corrosion resistance and can easily withstand the erosion of humid environments, various chemical cleaners, and corrosive gases. This fundamentally solves the problem of ordinary carbon steel equipment being prone to rust and having a short service life. The stainless steel surface is smooth and dense, making it difficult for dust, oil, and other pollutants to adhere, greatly reducing the possibility of bacterial growth.

Flexible operation, precise and controllable

Hand pull operation does not rely on electricity, reducing the dependence on power lines and avoiding the risk of downtime caused by electrical failures. It is especially suitable for places with unstable power supply or strict restrictions on electrical equipment. Operators can lift, lower, and move heavy objects by pulling the chain, with moderate operating force and easy control. The high transmission accuracy of the chain ensures smooth operation of the heavy object during lifting and lowering, without obvious shaking or stalling, and accurately positions the heavy object to the designated location. The manual chain hoist has a compact structure and occupies little space. When used in conjunction with a gantry, it can operate flexibly in limited space and meet lifting requirements under different working conditions.

Modular adjustable structure

The height of the gantry crane can be flexibly adjusted according to the required operational height, meeting the diverse layout needs of various factories. The specially designed bolt-type connection mechanism allows for assembly without the need for professional tools. The polyurethane universal casters with braking function facilitate easy movement and positioning. The anti-sway device can reduce load sway during lifting operations.

The structure is sturdy with strong load-bearing capacity

Based on different usage requirements, stainless steel gantry cranes can be designed in various specifications, with rated lifting capacities ranging from several hundred kilograms to several tons, capable of meeting a wide range of heavy lifting operations. The connection between the crossbeam and the legs of the gantry frame adopts a reinforced design, ensuring uniform stress distribution when bearing heavy loads, and avoiding structural deformation caused by excessive local stress.

For more product details or to obtain a customized solution, please contact our team of clean room lifting equipment experts. We will provide you with the most professional advice and services.