With the ergonomic and sterile lifting equipment from KUNFENG CRANES cleanroom cranes, you will be compliant with ISO classifications and all applicable laws and regulations.

Within the pharmaceutical industry, cleanrooms play a big role in the research and manufacturing of medicines, vaccines, production of other sterile medical products, and the packaging of these products. If these products are not produced in a sterile environment, this can result in product contamination which may result in reduced efficiency of the product and therefore, waste.

With the ergonomic and sterile lifting equipment from KUNFENG CRANES cleanroom cranes, you will be compliant with ISO classifications and all applicable laws and regulations.

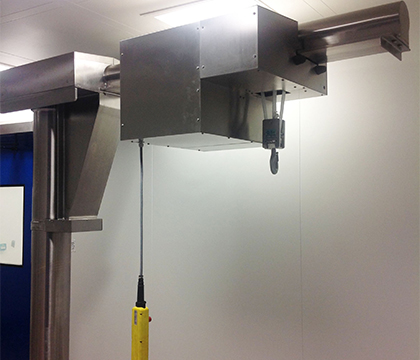

Due to the aggressive cleaning compounds, below-zero-conditions and exposure to steam and other high-temperature vapors, stainless steel cleanroom cranes are the most common lifting equipment in pharmaceutical cleanroom, cosmetic, and food processing environments.

Features

1. 304/316 Corrosion-resistant stainless steel frame, offers unmatched resistance to corrosion, acids, and alkalis, ensuring longevity and reliability in challenging conditions

2. Can be mounted: floor, ceiling, rail or wall.

3. 360 degree rotation for repetitive lifting work

4. Available in custom configurations: overhead cranes, gantry cranes, jib cranes, monorail cranes etc.

KUNFENG CRANES specialize in cleanroom lifting solution for over 15 years. We understand your lifting needs and provide the best stainless steel jib crane that relates to your application.

Clean room cranes are widely used in the pharmaceutical industry, including:

Medical production workshop

Biotech cleanrooms

Cosmetic production

Packaging workshop

Operating rooms

Examination rooms

Hospital laboratories

Applications of Pharmaceutical Cranes

Ingredient pouring from drums, hoppers and bulk bags

Form and mold handling

Loading feeding systems with caps, barrels and brushes

Pill and Vitamin Formers – powder loading and dumping

Contact Lens Manufacturing – powder handling

A “cleanroom” refers to a space which meets ISO14644-1 or FED Std 209E cleanroom classification standard. Cleanrooms can be thought of as “controlled environments” with added requirement of filtration / particle control.

ISO 14644 Cleanliness level of suspended particulates in cleanroom air | |||||||

CLASS | Number of Particles per Cubic Meter by Micrometer Size | FED STD 209E equivalent | |||||

0.1 µm | 0.2 µm | 0.3 µm | 0.5 µm | 1 µm | 5 µm | ||

ISO 1 | 10 | 2 | |||||

ISO 2 | 100 | 24 | 10 | 4 | |||

ISO 3 | 1,000 | 237 | 102 | 35 | 8 | Class 1 | |

ISO 4 | 10,000 | 2,370 | 1,020 | 352 | 83 | Class 10 | |

ISO 5 | 100,000 | 23,700 | 10,200 | 3,520 | 832 | 29 | Class 100 |

ISO 6 | 1,000,000 | 237,000 | 102,000 | 35,200 | 8,320 | 293 | Class 1,000 |

ISO 7 | 352,000 | 83,200 | 2,930 | Class 10,000 | |||

ISO 8 | 3,520,000 | 832,000 | 29,300 | Class 100,000 | |||

ISO 9 | 35,200,000 | 8,320,000 | 293,000 | Room Air | |||

Contact us today to get our stainless steel jib cranes and other pharmaceutical cleanroom hoists and cranes. And request a free quote or contact us for a custom solution.