With the increasing requirements for clean environment in industries such as pharmaceuticals, electronic semiconductors, biomedicine and food processing, material handling in clean rooms faces more stringent challenges in hygiene, safety and efficiency. Clean room adjustable mobile gantry crane is a high-standard lifting equipment that has emerged as a result. It integrates convenient movement, precise positioning and clean environment adaptation, and has become an indispensable material handling equipment for modern clean workshops.

Product Features of Cleanroom Adjustable Mobile Gantry Crane

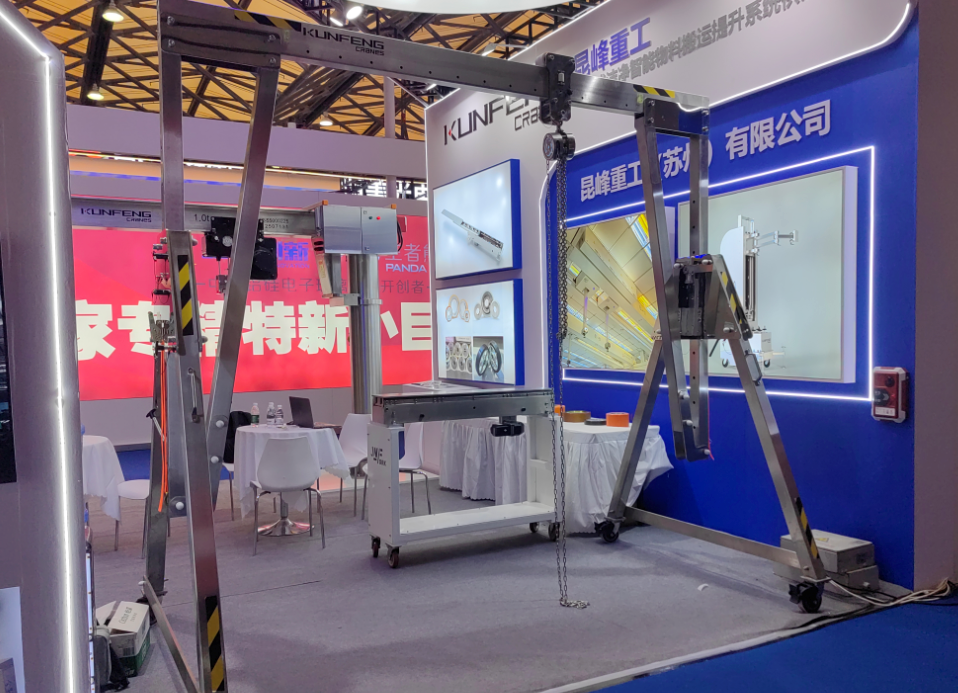

● All load-bearing parts are made of stainless steel, with smooth surface and no dead angle, which meets the clean level requirements of ISO 14644-1.

● It adopts universal casters, which are flexible to move and can achieve rapid positioning in horizontal and vertical directions without additional fixed tracks.

● Equipped with clean room electric hoists, it supports precise positioning and slow start/slow stop functions to ensure the stability of heavy objects during hanging and placing.

● The frame, span, height and drive mode can be flexibly combined according to the workshop layout and operation requirements.

● It has overload protection, limit switch, emergency stop button and anti-fall device to monitor the operation status in real time.

Adjustable Mobile Gantry Crane Technical Specifications Reference

Parameters | Technical Indicators |

Rated lifting capacity | 2000kg |

Lifting height | 3–6m (Customizable) |

Span | 4–12m (Selected according to the net width of the workshop) |

Gantry height | 4.5m (Including track height, customizable) |

Lifting speed | 8m/min (No load), 2m/min (Full load) |

Control mode | Handle remote control/button hanging control |

Material | 304 stainless steel |

Power supply | AC380V/50Hz |

Wheel type | Polyurethane coated silent universal wheel |

Application Scenarios of Cleanroom Adjustable Mobile Gantry Crane

● Pharmaceutical and biomedicine: In sterile workshops, filling production lines or vaccine development laboratories, cleanroom mobile gantry cranes can be used to transport raw material barrels, reactors and large-sized storage tanks to achieve contactless and fully enclosed material transfer and eliminate external contamination.

● Semiconductor and electronic manufacturing: In places that are extremely sensitive to dust, such as wafer manufacturing and chip packaging, gantry cranes with their stainless steel or aluminum alloy materials and low particle release design allow heavy-duty handling and precise placement to coexist, ensuring process stability.

● Food and beverage processing: In food production lines with higher cleanliness levels, such as aseptic filling and packaging areas, the equipment can quickly move large quantities of ingredients or packaging containers, and the smooth surface and rounded corner structure design facilitate daily cleaning and disinfection.

With its high cleanliness compatibility, flexible mobility and precise control capabilities, cleanroom mobile gantry cranes provide a safer and more efficient material handling solution for modern high-standard workshops. Contact us now to get more product details and customized solutions for cleanroom gantry cranes, so that your cleanroom will be more productive!