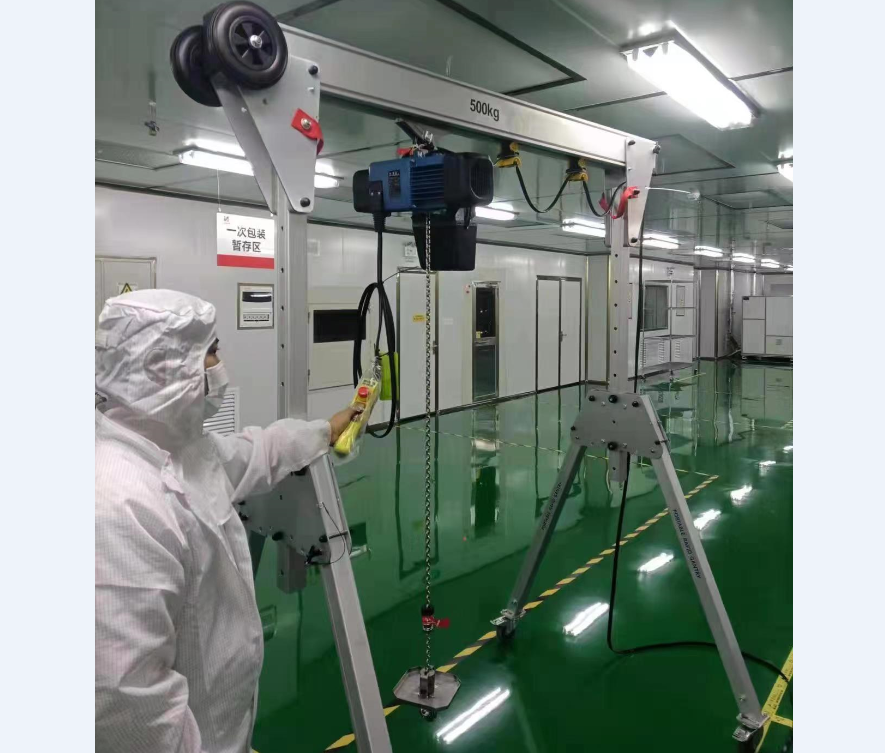

In a cleanroom environment, the choice of material handling system is crucial to the efficiency and sanitation of the production process. Lightweight aluminum adjustable gantry cranes are one of the ideal lifting equipment in cleanrooms due to their lightness, corrosion resistance, and easy cleaning. Whether it is the electronics, pharmaceutical, semiconductor or food processing industry, lightweight aluminum gantry cranes can provide efficient, safe, and dust-free handling solutions to ensure that the standards of the cleanroom environment are effectively maintained.

Cleanrooms have almost strict control standards for parameters such as air particles, temperature and humidity, and microorganisms. Traditional steel cranes are prone to rust, have excessive weight, and are difficult to clean thoroughly, which may bring the following hidden dangers:

● Risk of particle contamination: metal friction or coating peeling may produce particles;

● Many cleaning dead corners: complex structures are prone to dirt and increase the difficulty of disinfection;

● Low space utilization: bulky equipment occupies valuable clean areas and affects process layout.

Lightweight aluminum adjustable gantry cranes are designed for clean environments. From materials to design, they are centered on "zero pollution and high compatibility" to create an efficient and safe handling system for cleanrooms.

Core Advantages of Cleanroom Aluminum Gantry Cranes

● The dust-free design meets the strict requirements of cleanroom for equipment cleanliness and pollution-free.

● The span and height can be customized according to the size of the cleanroom, supporting single-track, double-track or multi-station layout.

● The components are lightweight, support rapid disassembly and reconfiguration, and adapt to production line upgrades or process adjustments.

● The precise control system makes the material more stable during handling.

● The maintenance-free design reduces the frequency of personnel entering the cleanroom and reduces the risk of contamination.

Typical application scenarios

● Pharmaceutical industry: transfer of sterile preparations, loading and unloading of freeze dryers, and handling of clean bottles and cans;

● Semiconductor manufacturing: wafer box transportation, maintenance of photolithography machine components, and dust-free storage management;

● Biological laboratories: incubator installation, sample cold chain transportation, and hoisting of high-value equipment;

● Medical device assembly: precision component positioning, aseptic packaging line integration.

Welcome to contact us for more customized solutions for cleanroom aluminum adjustable gantry cranes. We will provide the most suitable equipment configuration according to your needs to help your cleanroom production line run efficiently and safely.